Where does competitive pricing end and economic suicide begin?

There can be no doubt whatsoever that the past 12 months have been among the toughest that many in our industry have experienced. There has been precious little work available, and any work that has continued has carried with it wafer-thin or non-existent margins. Little wonder then that the demolition industry has cut its prices to keep men and machines working in the possibly vain hope that someone might reignite the light at the end of the tunnel.

However, there’s competitive pricing and then there’s desperate acts of economic suicide thinly disguised as competitive pricing. And it is our belief that the latest round of bidding from the US – this time on the demolition and decontamination of an Illinois steel plant – has ventured so far beyond financial prudency that it now serves only to mark the ongoing decline of the US demolition business.

Demolition News has been given an exclusive look at the prices received from the 15 that submitted a bid and it makes for staggering reading.

At the very top end of the bids, Dore & Associates submitted a price of $1,962,700, National Wrecking came in at $1,871,700 while well-known and respected companies including American Wrecking, Champion Environmental Services and Entact Environmental Services huddled either side of the $1.0 million mark.

But what marks the attached document as evidence of the world going mad is the $418,000 bid from local company, K Plus Environmental Services.

Now admittedly, they’re a local company so we should probably make allowances for the fact that their transport costs might be lower. They might also have a nice convenient location close by at which they can process or dispose of the arisings from the demolition works. And, given their environmental leanings, perhaps they are well equipped to handle the decontamination of a steel plant and all the chemical hazards this site is likely to throw up.

But do we honestly believe that they’re able to do all of this for around a fifth of the cost of the highest bid; or that they’re able to do it for less than half the bid prices submitted by some of the US’ most respected companies?

So who wins if such a low bid is successful?

Well, the city MIGHT win, assuming that the work can be carried out to their full satisfaction and environmental, health and safety standards at such a low price. And perhaps the contractor MIGHT win as this contract would undoubtedly keep his men and machines moving for a few months.

But one thing’s clear, the big loser in all of this is the US demolition industry. Such low prices do little more than reset the industry pricing benchmark and it could take months, years or even decades before pricing rises back to a level at which US contractors can make a reasonable profit whilst continuing to invest in “luxuries” such as training, health and safety, and new equipment.

The subject of low bidding is a current topic on the Demolition News Forum so please take the time to hit this link and let us have your thoughts.

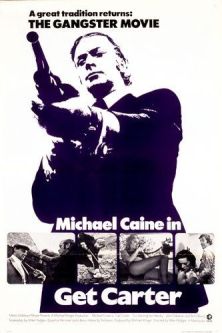

“You’re a big man but you’re in bad shape. With me, it’s a full time job. Now behave yourself.” Those immortal lines were spoken by Michael Caine’s Jack Carter character in the original 1971 movie “Get Carter” shortly before throwing that same big man over the edge of a multi-storey car park in the centre of Gateshead.

“You’re a big man but you’re in bad shape. With me, it’s a full time job. Now behave yourself.” Those immortal lines were spoken by Michael Caine’s Jack Carter character in the original 1971 movie “Get Carter” shortly before throwing that same big man over the edge of a multi-storey car park in the centre of Gateshead.